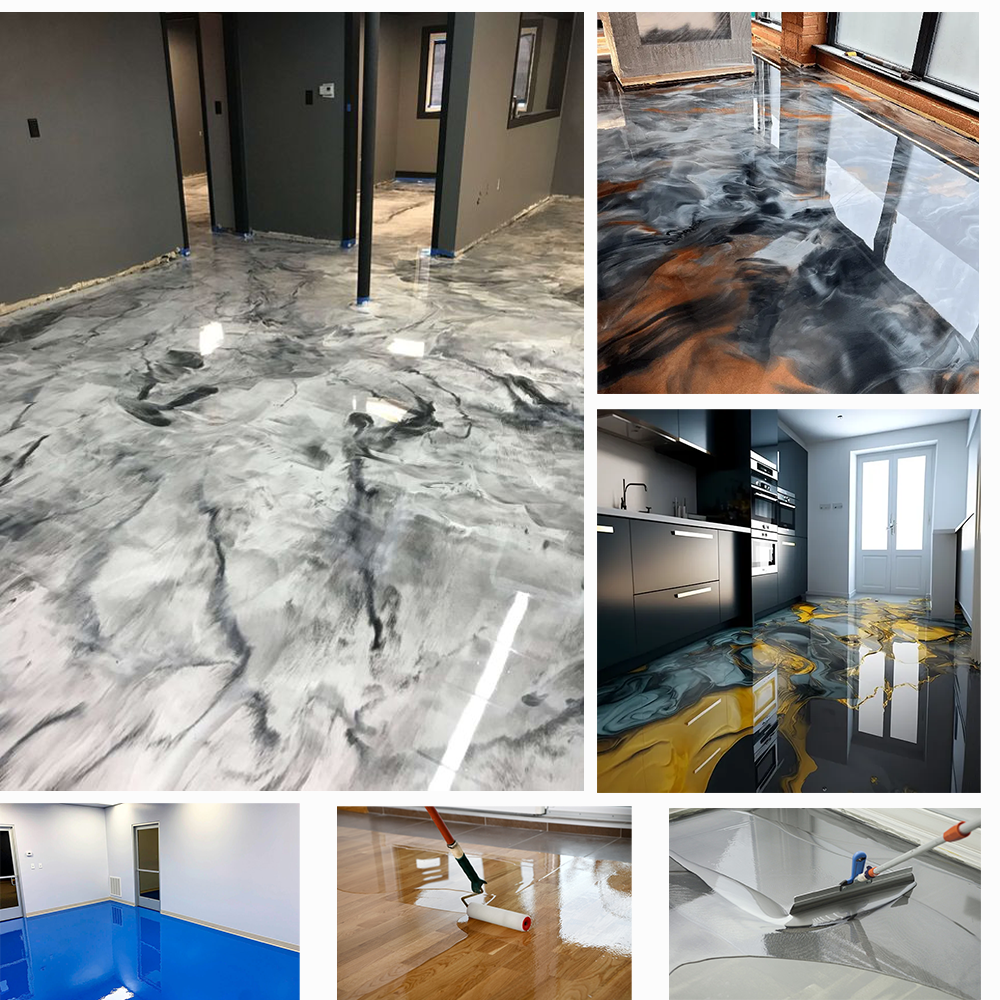

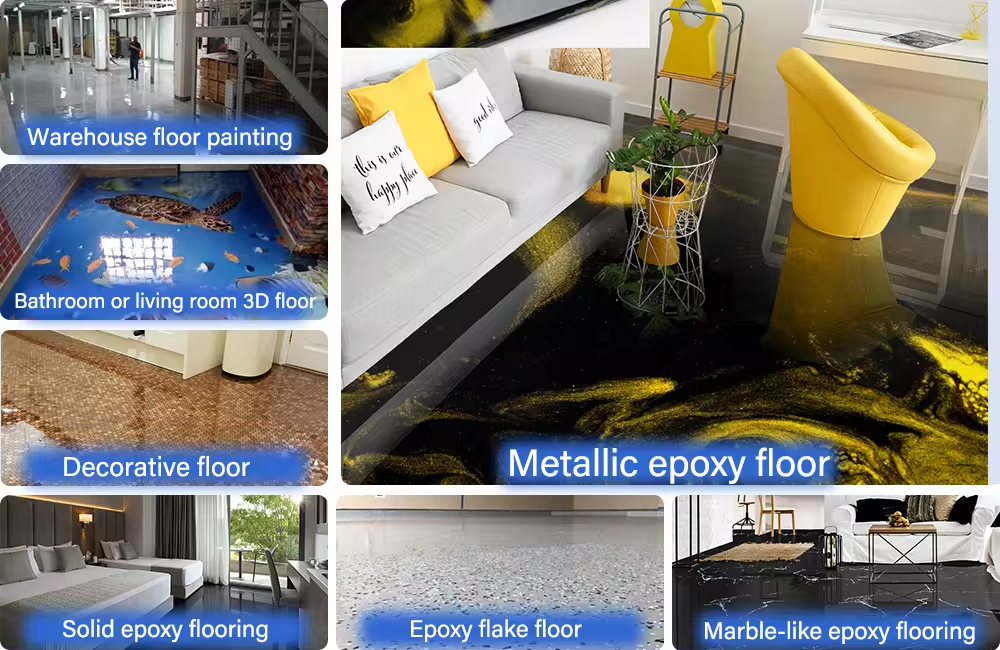

Epoxy Floor Resin system are the high-rated quality flooring products in the market ,it is most durable and easy to instal for any projects The metallic Epoxy floors are a seamless high-end and stunning look,which could be designed to cover existing interior concrete floors. It could be widely used for home ,garage,office ,showroom , shop, designer floor , industry or in fact just about anywhere.Can be used on all surfaces such as concrete, screed, wood and more.

Product feature :

High hardness 85~90D

100% Solids BPA free

Crystal Clear, High Gloss

Solvent free,odorless

No Toxic Organic Compounds,NO VOC

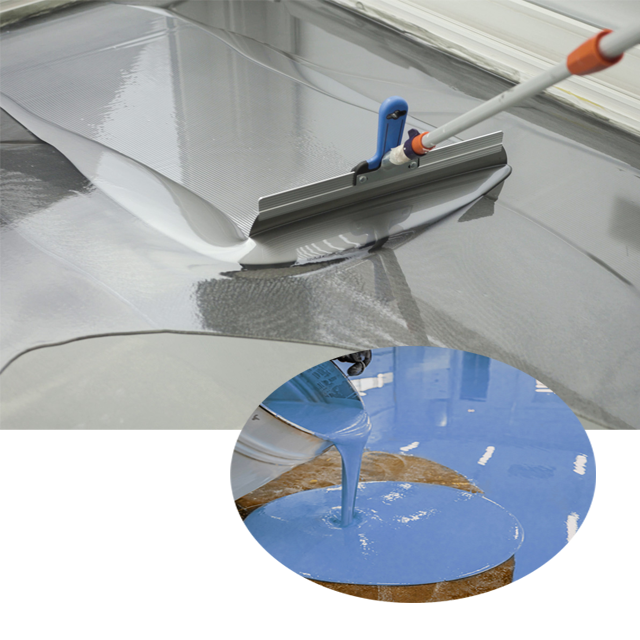

Self-Leveling

Extremely Durable,anti-scratich ,Anti slip

UV resistant(with anti yellow formula),

Bubble Free(with self bubble formula)

Tough Water Resistant & Waterproof

Eliminates Craters, Crawling and Fish Eyes

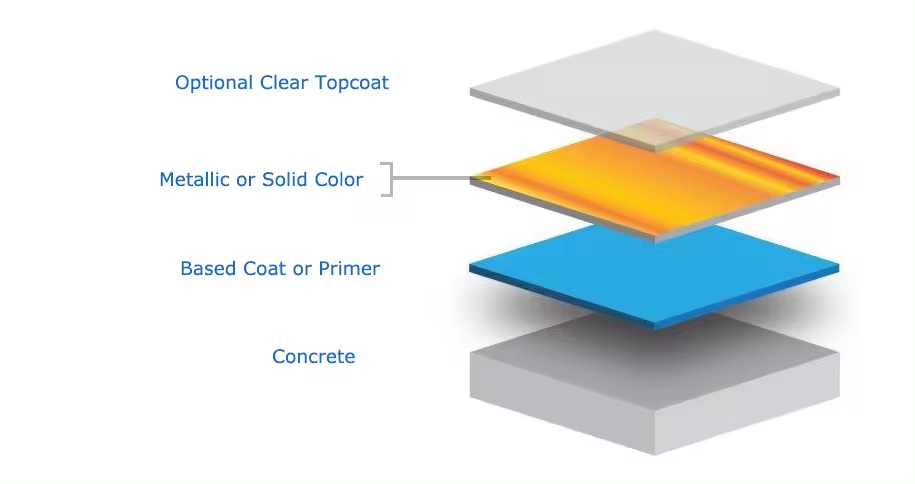

Including primer ,middle coating and top coating products systems

Will not blush or sweat under high humidity Will not distort with age Very easy to apply Good chemical resistance made with high quality raw materials Not considered flamble:FLAMMABILITY Class I

Specification

|

Part |

A | B |

| Color | Transparent | Transparent |

| Specific gravity | 1.15 | 0.96 |

| Viscosity (25℃) | 350-800CPS | 150 -350CPS |

| Mixing ratio | A: B = 2:1/3:1 | |

| Hardening conditions 25 ℃ | Light Foot traffic :24~48hours 72 hours for vehicular use and other heavy traffic. | |

| Usable time | 25℃×40min (100g) | |

| Usage | Primer (optoinal) : 0.1kgs per square meters thickness 0.1mm

Middle coating:thickness 1mm, require 1kgs per SQ.M . Coloring: 4~6% around (more or less will be as per color effect). 2 options of top:1) 0.3kgs epoxy per SQ.M; 2) 0.06kgs water based PU resin per |

|

| Application | Garage floor coating ,Industry floor coating ,Residential Floor coating ,Commercial floor coating and designer floors: showroom,shop,hotel ,or designer living space | |

| Free Samples | Available 200 grams to test quality | |

| Contact Us, We Will Provide You :

1. Good price with stable quality: WIN-WIN cooperation to support your business; 2. OEM with your target packing size and labeling your brands; 3.Fast delivery 3~5 days ,and logistic service support ; |

||

OEM Packing

Project processing

Steps epoxy flooring :

Usage:

for coloring for making designer floor , the ratio for the pigment to epoxy resin is 4~6% around (more or less will be as per color effect).

1.Seal the perimeter of the floor by using silicone sealant or epoxy adhensive to fill big gap;

1.Our epoxy coating resin has excellent self-levelling properties, so will only require light working to ensure that it has complete coverage and a consistent thickness – then the resin will do the rest of the work;

1.Whole processing will require 2 days around, the resin will be touch dry after 24hours, but should leave it much longer time before bring any furniture or heavy appliances;