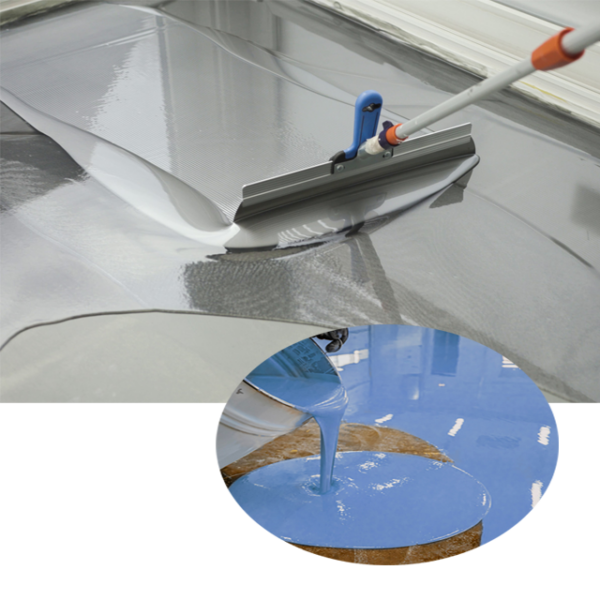

1.Our epoxy coating resin has excellent self-levelling properties, so will only require light working to ensure that it has complete coverage and a consistent thickness – then the resin will do the rest of the work;

2.A small spreader will be used for pushing the resin around any obstructions like pipework or a pillar, but for the bulk of the spreading it’s best to use a notched squeegee for speed and efficiency;

3.For big area,suggest 2 or more people to help mix ratio and pour ;

4.Our epoxy floor resin is well self-degassing so the bubbles will pop on their own,if floor is not presealed well,also may have few small area bubble,in this case just to overcome this we quickly passed over the surface with a propane torch to burst them.

Step 6: The Finished Floor and Application

1.Whole processing will require 2 days around, the resin will be touch dry after 24hours, but should leave it much longer time before bring any furniture or heavy appliances;

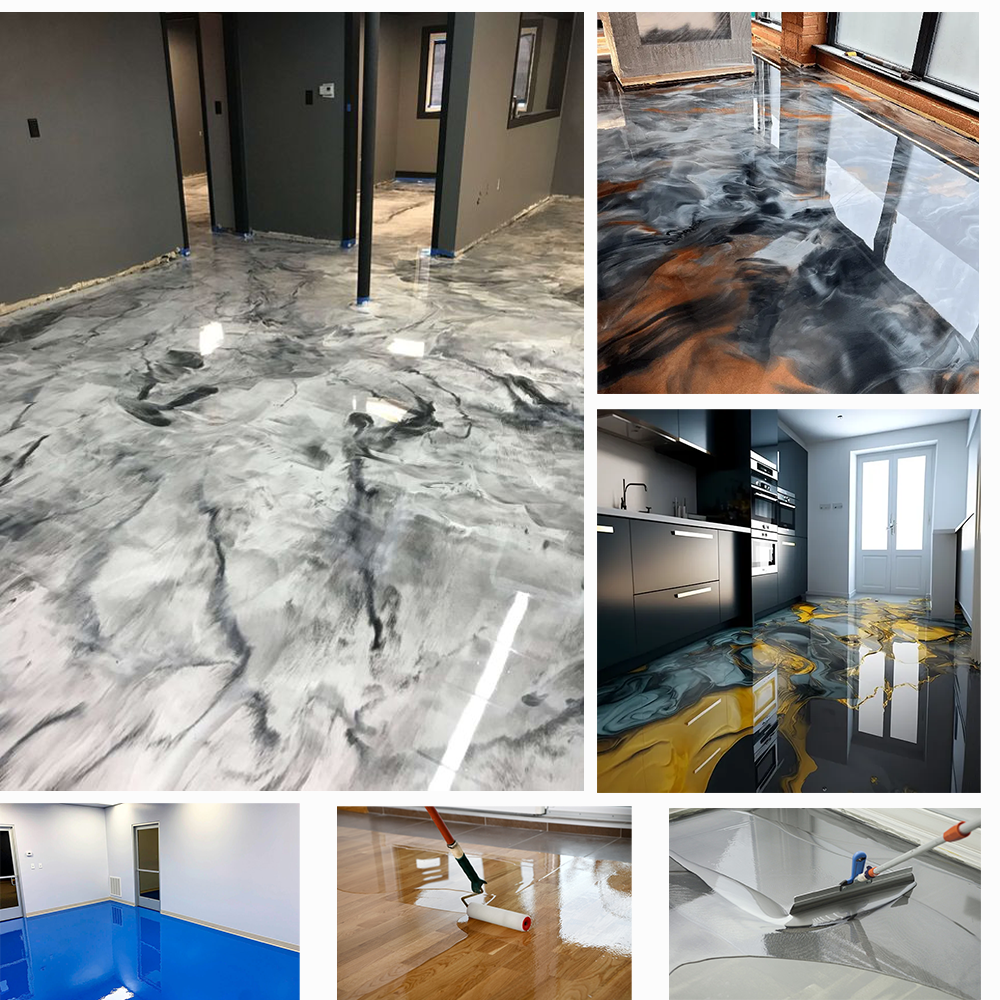

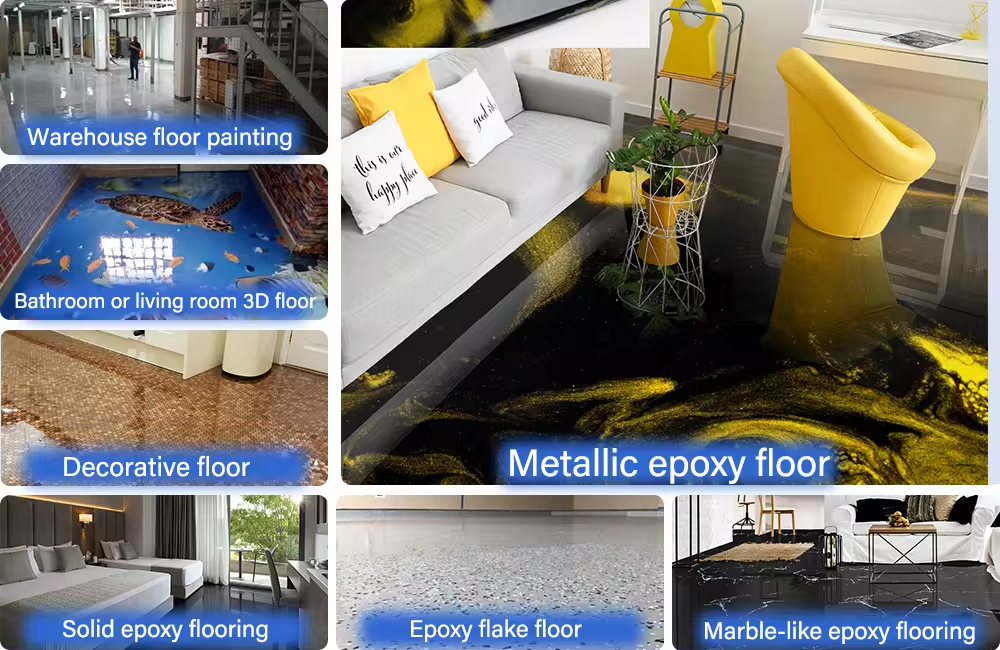

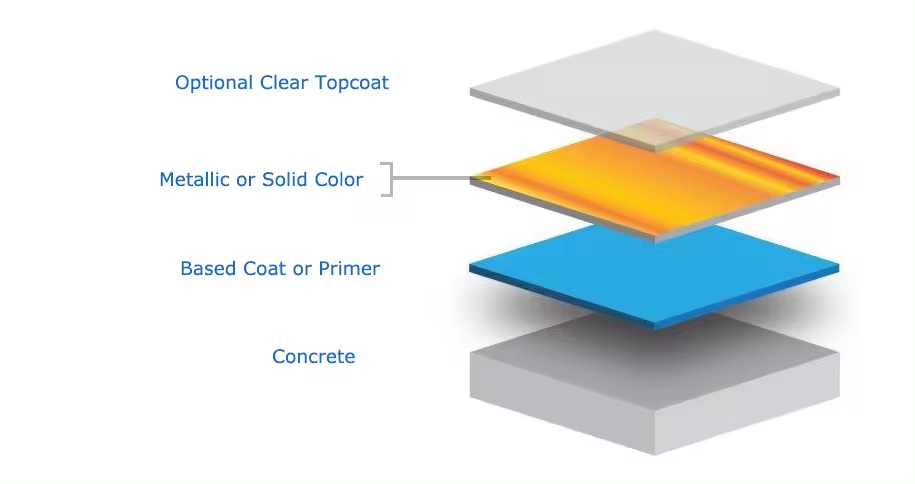

2.Single color or blended colour floor by combining solid color or metallic pigmemts to achieve a unique appearance.It will be also work by adding marbling or veins with metallic pigments or conntrasting colours, using the resin as a clear coat over a decorative floor like pennies, flakes,3D stickers ,vinyl records, crushed glass,mosaics and much more are all possibilities.

Application

For Garage floor coating ,Industry floor coating ,Residential Floor coating ,Commercial floor coating and designer floors:showroom, shop,hotel ,or designer living space!